专注于成为全球领先的

自动化解决方案平台

•1.5 Fold corrugated suction cups. •Seal lip soft and taper. •Bottom with support structure. •Top with clamps. •Complete size specifications. •Compensate the height difference of the workpiece, and have a good buffer effect when contacting the workpiece. •The workpiece with uneven surtace has good sealing. •Handling thin-walled workpieces will not cause permanent deformation. •Prevent the suction cup and the suction cup joint from loosening or falling off. •Suitable for various sizes and shapes of the workpiece. •Suitable for handling workpiece with uneven surface, such as carton, cardboard, curved workpiece, pipe, etc. •Suitable for handling fragile workpieces, such as electronic components, injection parts, etc. •Suitable for handling smooth wood, smooth steel plate, etc.

Details

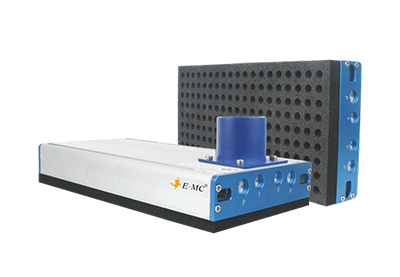

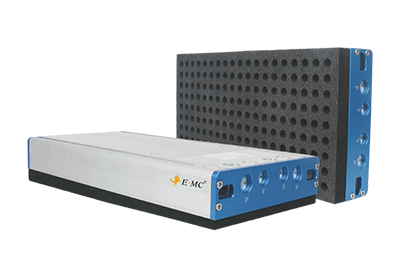

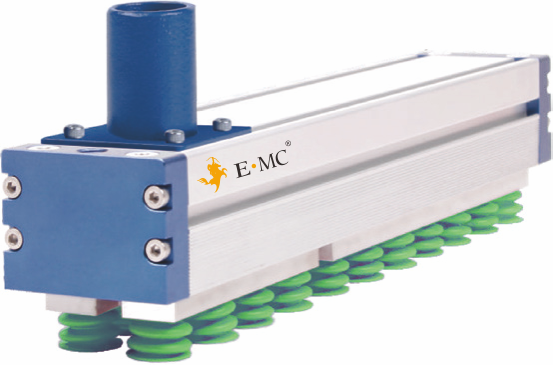

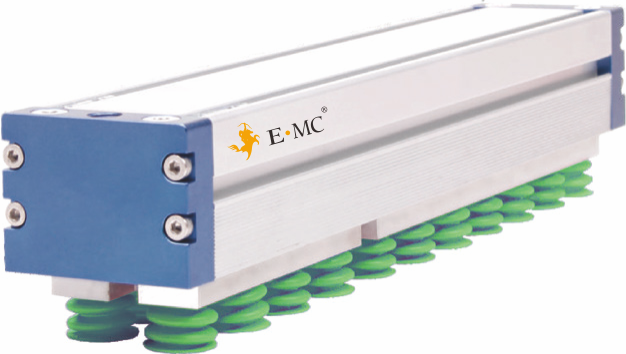

•Suitable for different industry products grabing, meet various specifications •Flexible selection of standard or customized gripper, suction of dfferent sizes can be freely combined and used. •Optional self- closing valve technology can solve workpieces with large vacuum leakage, uneven surface, different sizes and geometric shapes. •Vacuum source uses a built- in plug-in vacuum generator, lower air consumption, greater vacuum f1ow, shorter vacuum build- -up time. •Modular design for easy maintenance. •The interface is reserved, functionalcomponents can be directly added to the gripper, optimize the process, environmental protection and energy saving. •The material is aluminum alloy, engineering plastic and carbon fiber composite material, which is high strength and light weight. •Easy to nstall,with T-type removable mounting slider, available for fixing grippers as well as for mounting or mounting sensors. •Rubber gasket accessory for quick replacement.

Details

•Suitable for different industry products grabing, meet various specifications •Flexible selection of standard or customized gripper, suction of dfferent sizes can be freely combined and used. •Optional self- closing valve technology can solve workpieces with large vacuum leakage, uneven surface, different sizes and geometric shapes. •Vacuum source uses a built- in plug-in vacuum generator, lower air consumption, greater vacuum f1ow, shorter vacuum build- -up time. •Integrated plug-in vacuum generating device, which can be individually configured and quickly disassembled according to changing working conditions. •Modular design for easy maintenance. •The interface is reserved, functionalcomponents can be directly added to the gripper, optimize the process, environmental protection and energy saving. •The material is aluminum alloy, engineering plastic and carbon fiber composite material, which is high strength and light weight. •Easy to nstall,with T-type removable mounting slider, available for fixing grippers as well as for mounting or mounting sensors. •Rubber gasket accessory for quick replacement.

Details

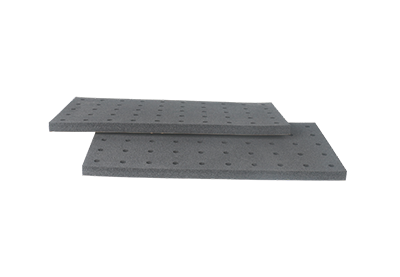

•Sponge gasket comes with self-adhesive. •Achieve fast and easy replacement. •No adhesive residue after replacement, no need to clean up the board. •Compresses and rebounds quickly for short beat work. •Filter function can be added under harsh dusty working conditions.

Details

•Suitable for different industry products grabing, meet various specifications •Flexible selection of standard or customized gripper, suction of dfferent sizes can be freely combined and used. •Optional self- closing valve technology can solve workpieces with large vacuum leakage, uneven surface, different sizes and geometric shapes. •Vacuum source uses a built- in plug-in vacuum generator, lower air consumption, greater vacuum f1ow, shorter vacuum build- -up time. •Modular design for easy maintenance. •The interface is reserved, functionalcomponents can be directly added to the gripper, optimize the process, environmental protection and energy saving. •The material is aluminum alloy, engineering plastic and carbon fiber composite material, which is high strength and light weight. • Easy to nstall,with T-type removable mounting slider, available for fixing grippers as well as for mounting or mounting sensors. •Rubber gasket accessory for quick replacement.

Details

•Suitable for different industry products grabing, meet various specifications •Flexible selection of standard or customized gripper, suction of dfferent sizes can be freely combined and used. •Optional self- closing valve technology can solve workpieces with large vacuum leakage, uneven surface, different sizes and geometric shapes. •Vacuum source uses a built- in plug-in vacuum generator, lower air consumption, greater vacuum f1ow, shorter vacuum build- -up time. •Integrated plug-in vacuum generating device, which can be individually configured and quickly disassembled according to changing working conditions. •Modular design for easy maintenance. •The interface is reserved, functionalcomponents can be directly added to the gripper, optimize the process, environmental protection and energy saving. •The material is aluminum alloy, engineering plastic and carbon fiber composite material, which is high strength and light weight. •Easy to nstall,with T-type removable mounting slider, available for fixing grippers as well as for mounting or mounting sensors. •Rubber gasket accessory for quick replacement.

Details

•Suitable for different industry products grabing, meet various specifications •Flexible selection of standard or customized gripper, suction of dfferent sizes can be freely combined and used. •Optional self- closing valve technology can solve workpieces with large vacuum leakage, uneven surface, different sizes and geometric shapes. •Vacuum source uses a built- in plug-in vacuum generator, lower air consumption, greater vacuum f1ow, shorter vacuum build- -up time. •Integrated plug-in vacuum generating device, which can be individually configured and quickly disassembled according to changing working conditions. •Modular design for easy maintenance. •The interface is reserved, functionalcomponents can be directly added to the gripper, optimize the process, environmental protection and energy saving. •The material is aluminum alloy, engineering plastic and carbon fiber composite material, which is high strength and light weight. •Easy to nstall,with T-type removable mounting slider, available for fixing grippers as well as for mounting or mounting sensors. •Rubber gasket accessory for quick replacement.

Details

•Suitable for different industry products grabing, meet various specifications •Flexible selection of standard or customized gripper, suction of dfferent sizes can be freely combined and used. •Optional self- closing valve technology can solve workpieces with large vacuum leakage, uneven surface, different sizes and geometric shapes. •Vacuum source uses a built- in plug-in vacuum generator, lower air consumption, greater vacuum f1ow, shorter vacuum build- -up time. •Integrated plug-in vacuum generating device, which can be individually configured and quickly disassembled according to changing working conditions. •Modular design for easy maintenance. •The interface is reserved, functionalcomponents can be directly added to the gripper, optimize the process, environmental protection and energy saving. •The material is aluminum alloy, engineering plastic and carbon fiber composite material, which is high strength and light weight. •Easy to nstall,with T-type removable mounting slider, available for fixing grippers as well as for mounting or mounting sensors. •Rubber gasket accessory for quick replacement.

Details

•Suitable for different industry products grabing, meet various specifications. •Flexible selection of standard or customized gripper, suction of dfferent sizes can be feely combined and used. •Optional self- closing valve technology can solve workpieces with large vacuum leakage, uneven surface, different sizes and geometric shapes. •Vacuum source uses a built- in plug-in vacuum generator, lower air consumption, greater vacuum f1ow, shorter vacuum build- -up time. •Modular design for easy maintenance. •The interface is reserved, functionalcomponents can be directly added to the gripper, optimize the process, environmental protection and energy saving. •The material is aluminum alloy, engineering plastic and carbon fiber composite material, which is high strength and light weight. •Easy to nstall,with T-type removable mounting slider, available for fixing grippers as well as for mounting or mounting sensors. •Rubber gasket accessory for quick replacement.

Details

•Suitable for different industry products grabing, meet various specifications •Flexible selection of standard or customized gripper, suction of dfferent sizes can be feely combined and used. •Optional self- closing valve technology can solve workpieces with large vacuum leakage, uneven surface, different sizes and geometric shapes. •Vacuum source uses a built- in plug-in vacuum generator, lower air consumption, greater vacuum f1ow, shorter vacuum build- -up time. •Integrated plug-in vacuum generating device, which can be individually configured and quickly disassembled according to changing working conditions. •Modular design for easy maintenance. •The interface is reserved, functionalcomponents can be directly added to the gripper, optimize the process, environmental protection and energy saving. •The material is aluminum alloy, engineering plastic and carbon fiber composite material, which is high strength and light weight. • Easy to nstall,with T-type removable mounting slider, available for fixing grippers as well as for mounting or mounting sensors. •Rubber gasket accessory for quick replacement.

Details