专注于成为全球领先的

自动化解决方案平台

1. Please check whether the product is damaged during transport, and check the technical parameters (such as operating voltage, working pressure, working temperature, etc.) to confirm whether they satisfy the requirements before installation.

2. Please pay attention to the air flow direction during installation, P(1) is air inlet、A(2)/B(4) is working port、R(3)/S(5) is exhaust port, working medium must be filtered through 40um filter(higher filter precision is available).

3. Before installation,the pipeline should be completely cleaned (Propos to use air guns or empty the pipeline directly before connection) toremove pipeline dust, debris and oil, so that to avoid the influence of valve action (such as stuck, no response or response slowly, etc.),avoid noise from damaged spool and the working life reduction.

4. When using fitting with thread to connect the valve and tubing, not allowed the thread dust and sealing tape fragments into the valve body;When using the sealing tape, the thread end should be set aside1 or 2 thread pitch non-winding sealing tape;When using liquid glue,should avoid excessive liquid glue going into the valve body.

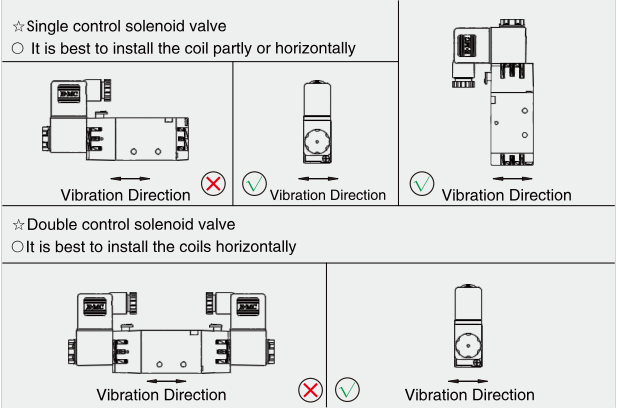

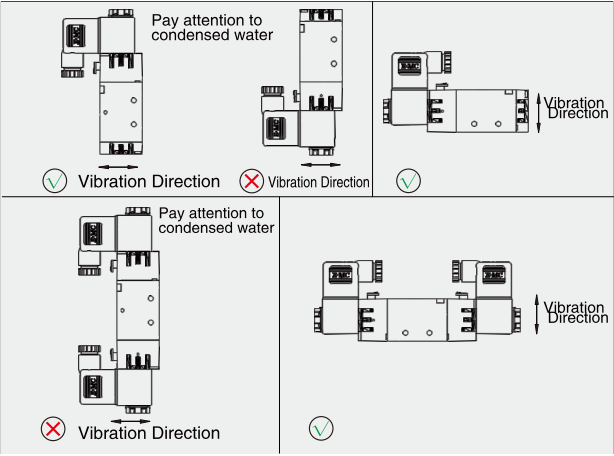

5. Try to avoid using the valve in vibration environment ; if slight vibration, please make the vibration direction and spool action direction at right angle to avoid the influence of the spool.

6. ln order to prevent condensate water, oil ,etc flowing into the coil, it is better to make the coil upwards or adopt lateral installation.

7. Try to install the valve as close as possible to the cylinder, to avoid theinfluence of active time because of the long pipeline and air consumptionincrease.

8. When manifold assembly used, please note back pressure phenomenonthat caused by incompletely exhaust.Please note wrong action caused by the interaction between the valves. Especially when using the 3 positionscenter exhaust valve and single acting cylinder, recommend to inlet andexhaust separately.

9. When using 3 positions center close or 3 positions center pressure valvesit is difficult to guarantee the cylinder stop exactly at any intermediate positionbecause air compressibility and reasonable leakage of valve and cylinder.lf require to stay at the stop position for a long time, please take other methodssuch as using induction check valve together).

10. When using 3 positions center close valve, please consider the residual pressure release between the valve and cylinder , please set the residualpressure release function in the air circuit .

11. When using internal pilot type, please consider minimum operating pressure not allowed to throttle at inlet ,either exhaust emptied directly , to avoid wrong action caused by big air pressure reduction. lf blowing environment, pleaseuse external pilot type.

12. Pilot valve, piston cavity, breathing hole and pilot valve exhaust port shallnot block or restricted, and the filter need to do regular cleaning or replacement if necessary

13. It is recommended to install muffler to the exhaust port to avoid inhaling of impurity into the valve body.

14. Such as valves used in vacuum condition, should use direct acting valve or exterior pilot type valve, and measures should be taken to prevent dust from sucking in the suction cup

15. Double electric air control valve has memory function (except threeposition valve), power up time should be more than 0.1s in time to ensure the valve reversing in place.

16. Although the coil calibration is 100%ED, long time continuous electricity will cause overheating, accelerated insulation aging, reduce the performanceof the solenoid valve、lifetime and energy, so in the condition of continuouspower on,we should consider to use double electronically controlled solenoid valve with memory function or adopt energy saving and low power coil, in order to extended coil life , and save energy.

17. Solenoid valve installed in the control cabinet,We should pay attention to the ventilation of the control cabinet, heat radiation, to ensure that the temperature in the cabinet within the safety use range.

18. Solenoid valve coil should not be connected to the wrong voltage (such asthe DC24V coil connect to the AC220V voltage), Otherwise, the coil will beburned, and the working voltage should be in the required voltage range,to make sure the valve works well.

19. Since DC solenoid valve has polarity indicator light, please pay attention tothe positive and negative poles when wiring, "1" connect the positive pole,and "2" connect the negative pole, If the positive and negative poles are reversed, The light will not turn on, but the valve can still be actuated.

20. During use energy saving and low power consumption coil solenoid valve,please refer to energy-saving, low-power solenoid valve instructions.

21. The valve on this catalogue shall not be used as an emergency shut-offvalve. lf the emergency shut-off function is required, other ways of ensuring safety shall be used to control it.